The Technology

The process is determined by the energetic utilisation of substantially not further treatable organic waste.

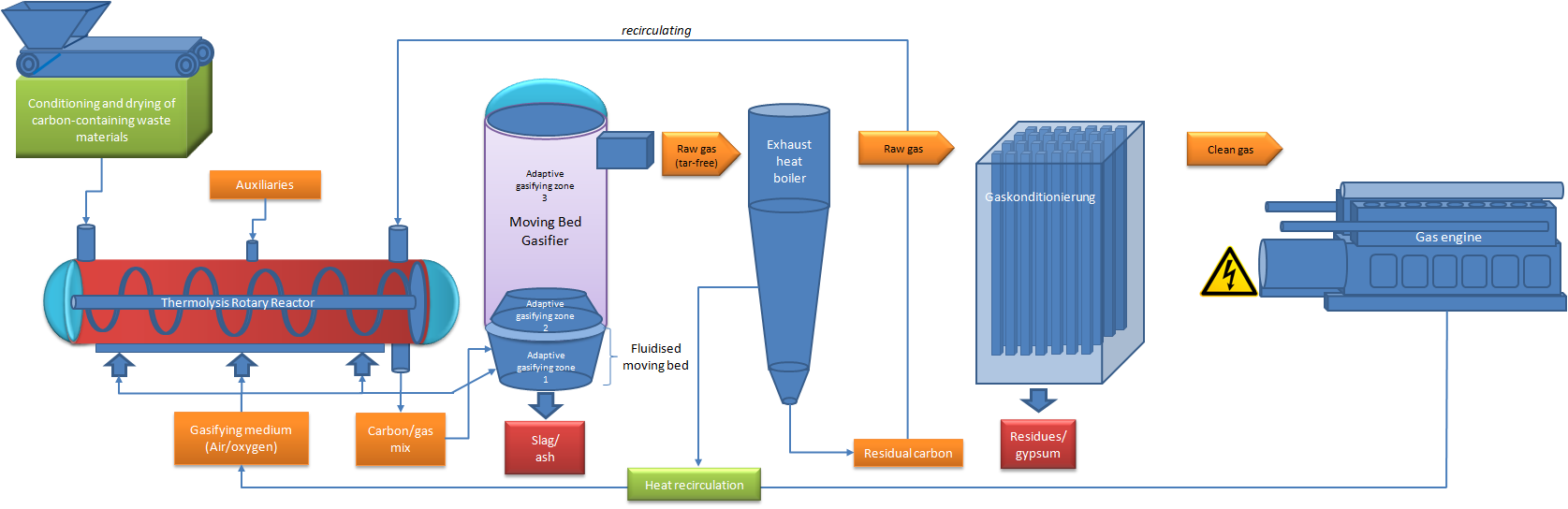

The patent-secured INTEC Technology involves a closed and thus completely emission-free thermal waste treatment primarily consisting of the procedural steps degassing/smouldering (thermolysis) and gasification. The INTEC Thermolytic Cracking Process operates with coupled procedural steps, yet in spatially separated devices. With this system, the respective necessary process parameters can be optimally adjusted, allowing an above-average utilisation by more than 99 % of the energy content of the waste material applied.

The generated synthesis gas is primarily utilised in gas engines which drive low or medium voltage generators according to the customers' requirements regarding electricity generation. By additional application of exhaust heart from the engines in downstream ORC units (Organic Rankine Cycle), the electrical efficiency reaches up to 48 %.

The INTEC Synthesis Gas Systems are characterised by a particularly consequent utilisation of the accrued exhaust heat for maintaining the overall process.

Process Scheme:

Characteristics of the Process

- Power generation of up to 1.5 MWh from one tonne of organic waste

- Carbon conversion to synthesis gas more than 99 %

- Thermal total efficiency degree approx. 88 %

- High availability due to modular and redundant design

Environmental Benefits of the INTEC Thermolytic Cracking Process (INTEC-TCP®):

Further Advantages

- Most modern technology Made in Germany

- Administrative approval in Germany for plant operation

- Very low electricity generation costs per kWh

- High profits for the operator

enlarge image

enlarge image